Strength in Unity: Understanding Welded Wire Mesh Panel Joinery

Welded Wire Mesh Panel joinery plays a crucial role in reinforcing structures, offering a solid and resilient foundation for a variety of applications. Understanding the intricacies and benefits of this joinery method is essential for engineers, architects, and builders. In this article, we delve into the concept of strength in unity through a comprehensive exploration of Welded Wire Mesh Panel joinery.

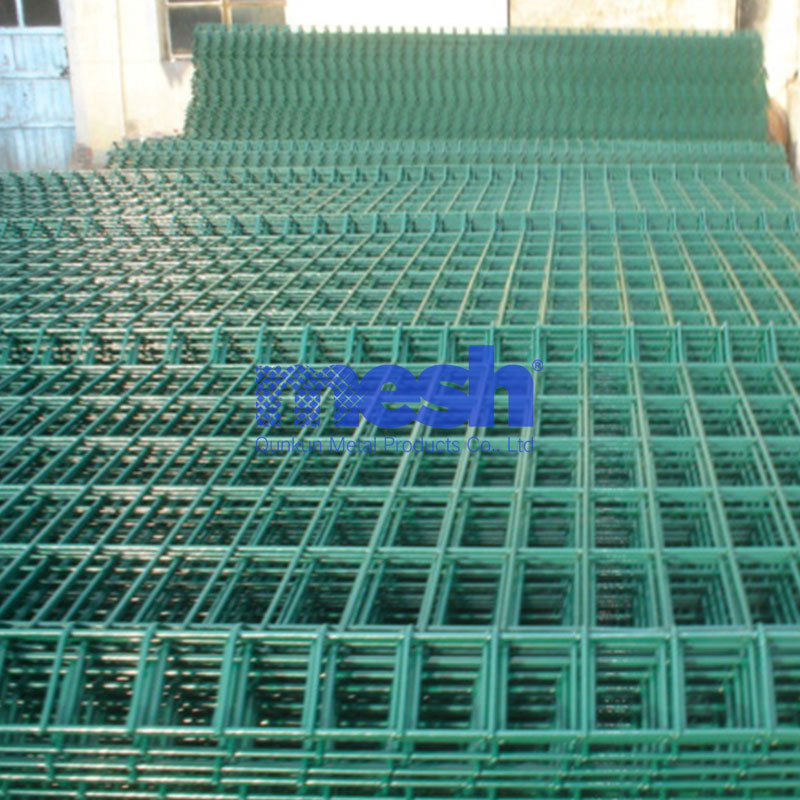

Welded Wire Mesh Panels are composed of a network of wires that are welded together at precise intersections, creating a robust, unified structure. The welding process is a pivotal aspect of the panel's strength and durability. By fusing individual wires at specific points, the overall panel gains significant strength and stability, making it an ideal material for various industrial, construction, and commercial applications.

The tight welds in Welded Wire Mesh Panels ensure that the structure can withstand substantial loads and forces. This characteristic is critical in applications where strength and structural integrity are paramount, such as retaining walls, fencing, and flooring systems. The joinery technique creates a unified matrix, distributing the stress evenly and enhancing the load-bearing capacity of the panel.

In conclusion, Welded Wire Mesh Panel joinery exemplifies the concept of strength in unity. The meticulous welding process creates a seamless and robust structure, offering superior strength, durability, and load-bearing capacity. This joinery technique not only streamlines construction processes but also contributes to sustainable practices through reduced material usage. Engineers and builders can harness the potential of Welded Wire Mesh Panels to construct resilient and reliable structures that stand the test of time.

-

Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China